ENGINEERED FOR EFFICIENCY, SPEED, AND SUPERIOR HEAT TRANSFER

Custom-Designed Drying & Curing Solutions for Manufacturing Leaders

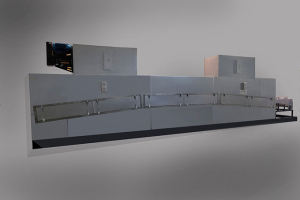

For over 65 years, Glenro has been a trusted industrial oven manufacturer, providing precision-engineered hot air dryers and ovens that enhance efficiency, optimize energy use, and ensure uniform drying results. Whether you need high-speed curing, moisture removal, or precision heat control, Glenro designs and manufactures customized drying systems tailored to your exact process needs.

From non-contact flotation dryers for delicate materials to high-speed impingement systems for rapid moisture removal, Glenro delivers proven solutions for manufacturers who demand reliability, consistency, and performance.

CUSTOM-ENGINEERED INDUSTRIAL HOT AIR DRYERS & OVENS

Glenro specializes in four advanced drying technologies, each designed to maximize heat transfer efficiency, improve product quality, and reduce energy consumption. Need a custom drying solution?

FLOTATION DRYERS: NON-CONTACT DRYING FOR COATED & DELICATE MATERIALS

Best for: Packaging films, adhesives, coatings, and specialty papers.

- Uses heated air to support materials from above and below, eliminating mechanical contact.

- Ideal for double-sided coated webs, films, and lightweight substrates.

- Prevents wrinkling, marring, or uneven drying while ensuringuniform heat distribution.

IMPINGEMENT DRYERS: HIGH-SPEED MOISTURE & SOLVENT REMOVAL

Best for: Automotive adhesives, textiles, industrial coatings, and web drying.

- Delivers high-velocity air jets to break boundary layers and enhance heat transfer.

- Achieves faster drying times with uniform temperature control.

- Custom nozzle configurations maximize airflow efficiency for different materials.

THROUGH-AIR DRYERS: PRECISION DRYING FOR POROUS & FIBER-BASED PRODUCTS

Best for: Nonwovens, fiberglass, textiles, and high-performance insulation materials.

- Forces heated air through the material, ensuring even heat penetration.

- Prevents surface scorching while achieving deep drying consistency.

- Energy-efficient design with optimized airflow control.

COMBINATION HOT AIR / INFRARED SYSTEMS: MAXIMUM EFFICIENCY & THROUGHPUT

Best for: Coated textiles, paints, lacquers, and moisture-sensitive materials.

- Integrates infrared heating with hot air convection for accelerated drying.

- Reduces overall energy consumption while enhancing drying speed.

- Provides precise control over moisture content and temperature profiles.

WHY CHOOSE GLENRO FOR INDUSTRIAL DRYING SOLUTIONS?

Process-Driven Engineering for Maximum Performance

At Glenro, we don’t just build ovens—weengineer solutions that optimize your entire production process. Increase your throughput with a custom Glenro drying system:

Proven Heat Transfer Expertise

Over 65 years of experience in designing high-efficiency drying systems.

Custom-Built for Your Production Line

Tailored systems designed to maximize throughput and efficiency.

Precision Airflow & Temperature Control

Uniform drying across all material types and substrates.

Energy Efficiency & Cost Savings

Reduce heat loss and operational expenses with optimized designs.

Seamless Integration

Systems designed for new installations or retrofits into existing production lines.

INDUSTRIES & APPLICATIONS

Glenro’s hot air dryers and ovens are used by leading manufacturers across multiple industries for precise, high-efficiency drying and curing applications.

Not sure which drying system fits your process?

WORK WITH GLENRO– LET’S BUILD YOUR SOLUTION

Your drying and curing process is critical to your production success—which is why Glenro deliverstailor-made solutions that enhance efficiency, reduce costs, and ensure consistent product quality.